Best Accounting Software for Manufacturers

Suppose you are one of those responsible for managing a factory and want to choose a software to manage the accounting operations in your factory. In that case, it is normal to feel worried about your decision. This is because not all manufacturing software can efficiently manage the manufacturing process. Since manufacturing is a sensitive process, if the system is not reliable, you are likely to be exposed to significant losses. But in your opinion, what is the best accounting software suitable for managing factories? And how, if a software is presented to you, can you know that it is the right one for your factory?

Problems We Face in the Absence of a Factory Accounting System

Remember that using factory accounting software has become a necessity, not a luxury. In addition to providing many features and advantages, it will solve many problems that you face while managing your factory. If you do not use an accounting system for the factory, you may face some problems in managing the factory. Here are some examples:

1- Wasting Time:

The Daftra software will benefit you in managing the manufacturing system in a way that integrates with other departments and links them to each other, and it also organizes work within the factory in several areas. You can benefit from the Dafta accounting software in the manufacturing process in several points:

2- Lack of Organization:

Daftra’s accounting system enables you to create manufacturing orders and simple production orders, and it also allows you to add a new composite product that includes multiple existing products or components used in its manufacture.

3- Data Entry Errors:

Without a reliable accounting system, errors can occur when entering accounting and financial data. Such an error may give a misleading impression of the factory’s financial condition and can affect the effectiveness of financial reports and analysis. That is why it is important to realize that using accounting software in managing factory accounts is an effective solution to these problems, improving factory management. It is also worth noting that using a factory accounting system helps improve the efficiency of factory management and supports making correct decisions.

Best Accounting Software for Factories

And to help you choose from among the many software, we have compared the top 5 software for managing factory accounts:

- Daftra Business Management software

- Midad ERP

- PhenixSoft (Phenix)

- AccFlex

- ERPNext

We will address them from all sides, explaining the features available in each software and the most important advantages:

1- Daftra

The Daftra software will benefit you in managing the Manufacturing Management Software in a way that integrates with other departments and links them together, organizing work inside the factory across several areas. You can benefit from Daftra accounting software in the manufacturing process in several ways:

Creating Manufacturing Orders:

Daftra’s accounting software enables you to create manufacturing orders and simple production orders, and it also allows you to add a new composite product that includes many existing products or components used in its manufacture.

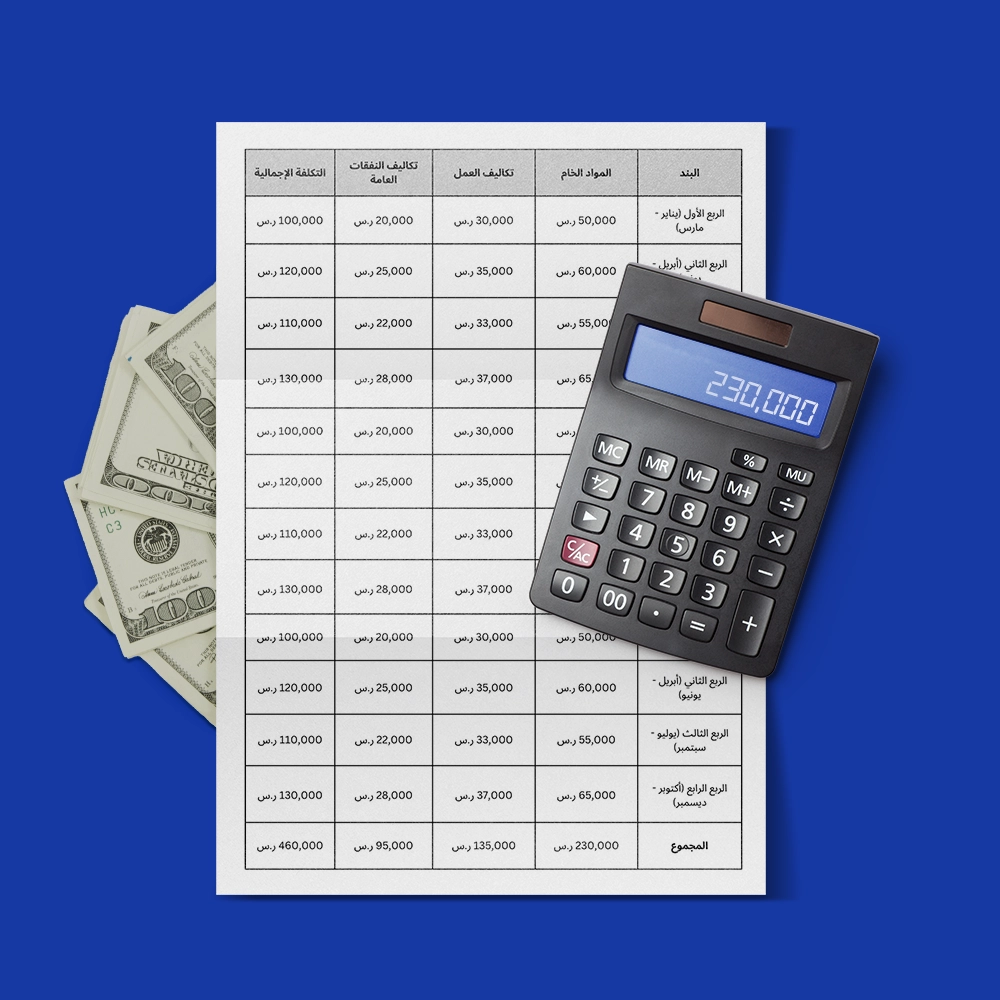

Tracking Raw Material Consumption in Manufacturing:

You can track the consumption of raw materials during production and determine the quantities of items or raw materials currently available in the warehouse, and their storage location, to make them easier to access.

Automatic Cost Calculation:

The Daftra accounting software automatically calculates costs, enabling you to obtain accurate estimates of production costs and analyze the profit and loss of each product.

Integrating Manufacturing and Accounting Operations:

With Daftra’s accounting system, you can fully integrate manufacturing and accounting operations. This enables easier management of processes and informed strategic decisions based on the financial data and reports generated by the system.

Manufacturing Outputs:

Using Daftra accounting software helps track outputs and their accounts accurately and systematically, and it can provide detailed reports and analyses of factory operations and production.

Inventory Management:

Through Daftra’s accounting software, you can track all inventory movements associated with your factory, starting from purchases, warehouse division, and sales orders, in addition to the ability to track batch numbers or serial numbers at early or final stages, anywhere along the supply chain.

Labor System:

Daftra provides features that facilitate managing labor affairs in the factory — from the organizational structure, determining worker shifts during the week, organizing attendance and departure, managing leave, to automating payroll and generating detailed reports about labor costs. For example, if you own a leather factory, you may have a certain number of workers, and each worker is assigned a specific number of hours divided into shifts. With Daftra, you can add the worker with their shift details so that wages are calculated based on working hours, while also organizing their presence times and productivity. Other Features of Daftra:

Customizable:

Daftra’s software offers flexibility within the system to suit customer needs. You can choose the subscription package that best fits your accounting requirements, add custom accounting accounts as needed, and select the financial reports you want to generate and use in the system.

System Integration:

Daftra’s accounting system fully integrates manufacturing, inventory, sales, customer management, production, and industrial cost management. With this integration, you can track your factory’s financial operations thanks to the connectivity of its different modules and functions.

Free Trial:

Daftra provides a free 14-day trial version to help you evaluate the system, explore its services, and understand its functions. It allows unlimited basic users, with an additional fee of $5 per month for each extra user.

Technical Support:

The system includes technical support that will serve your factory if any problems arise. You’ll find free support available to assist you with any issues you face.

Educational Guide:

Daftra includes a comprehensive step-by-step guide with images, as well as videos that explain each step in the system and how to perform every process. These resources can be used when adding new functions while managing factory operations.

Monthly and Annual Pricing Plans:

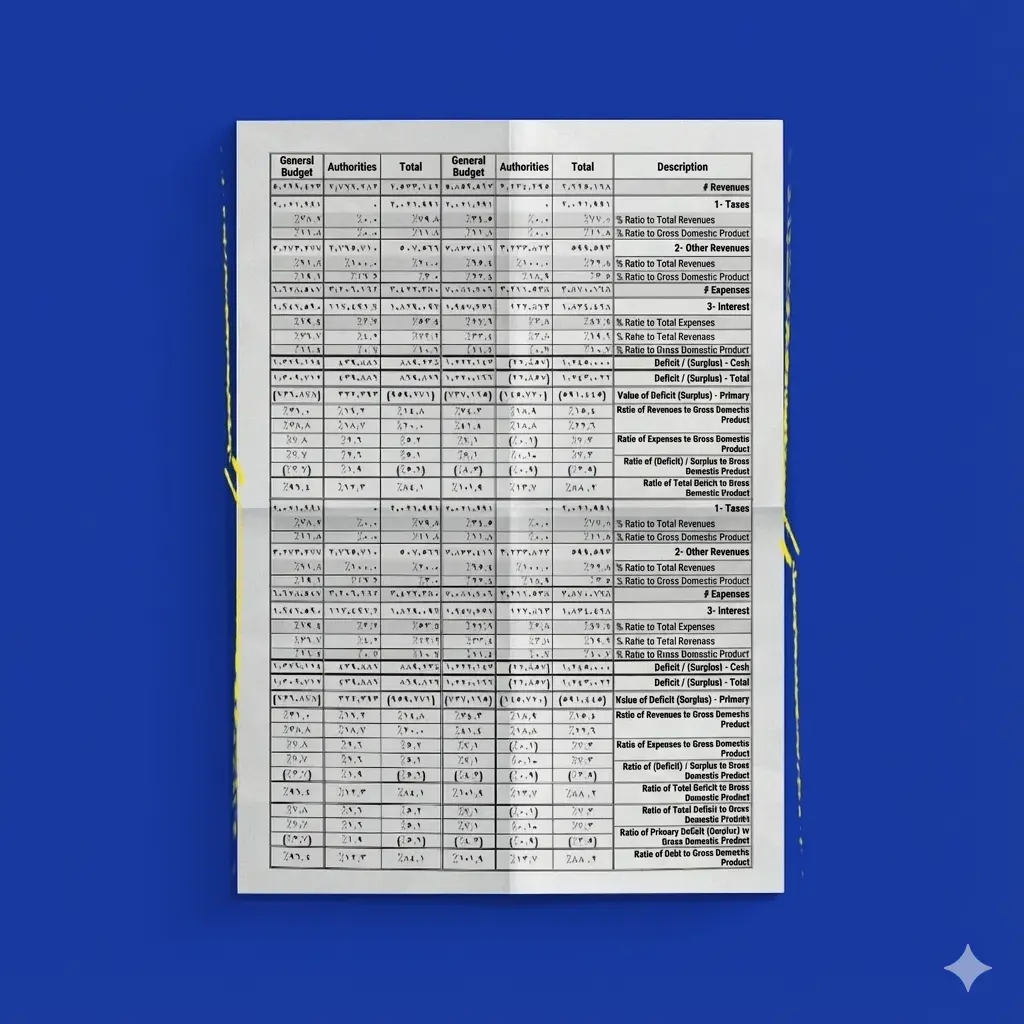

| Plans | Basic Plan | Advanced Plan | Comprehensive Plan |

| Monthly package price | $9.99/month | $19.95/month | $40/month |

| Annual package price | 120/year | 239/year | 480/year |

Read Also: Best Self-Employed Accounting Software in Saudi Arabia

User Reviews:

check more of user reviews here

2- Midad ERP

Midad ERP is a simple and integrated accounting software for managing factories and small and medium-sized companies. The Midad team has extensive experience in accounting software and applying it to local and international standards. It allows you to control all your accounting operations online, regardless of your location.

Account Management:

Midad ERP’s accounting system provides functions related to managing production cost accounts, production operations, and labor organization, including:

Production Costs and Operations Management:

Midad offers tools and reports to manage production costs in the factory. It allows you to set project components once, automatically calculate the current cost of those components, and issue manufacturing documents automatically.

It also calculates the final product cost automatically (including expenses beyond raw material costs). This helps track both direct and indirect costs related to the manufacturing process, identify raw material, labor, and other expenses, and coordinate across departments while automatically tracking workflow tasks.

Warehouse Management

Through its warehouse management module, the system enables easy transfer of products and raw materials between warehouses or branches, with the ability to specify transferred quantities effortlessly. It also automatically calculates the final product cost, including any additional expenses beyond raw material costs.

Labor Organization:

Midad provides tools to organize workers, tasks, and schedules. You can assign tasks, distribute shifts, and track workers in the factory. The system keeps a complete file for each worker, including personal information, certifications, years of experience, joining date, bank account, liabilities, and more.

Features of the Integrated Midad Accounting System

Midad offers a set of features that can meet some of your needs in managing accounts and production within your factory:

Technical Support & Free Trial:

Midad provides a 7-day free trial, with the possibility of renewal upon request to the sales team. This is accompanied by 24/7 technical support—either via WhatsApp or by submitting a ticket, after which the team will respond. For subscribers, the first year of technical support is free.

Educational Guide:

The system provides an educational guide with recorded training videos to help you understand its functions and use them effectively, answering the most common user issues.

Subscription Cost & Users:

Midad’s accounting system offers subscription plans tailored individually for each client, according to different organizational needs. Each package allows only two users by default, with the option to increase users at an additional cost.

Disadvantages of ERP supply software:

Here are some disadvantages to be aware of before using Midad ERP for accounting:

- System installation takes a long time.

- High cost of hiring specialized personnel.

- Migrating data from old systems to Midad ERP takes a long time.

- Formatting and organizing data for use with the new system can be difficult.

Midad ERP Pricing Plans

| Package | Midad Online | Midad Professional | Midad Lite |

| Monthly Price | $103 per month + $41.20 for adding the HR system | Price pending | Price pending |

3- Phenix (PhenixSoft)

Phenix provides you with all the tools you need to manage manufacturing through powerful features for displaying data, costs, and profits. It performs a wide range of manufacturing operations, including:

Creating a Factory Warehouse

You can set up dedicated warehouses for raw materials, semi-finished products, and finished goods.

Organizing Production Records

The system allows you to structure production records and manage manufacturing templates in a defined sequence according to production stages, enabling the product to pass through a series of processes until the final material is produced from raw inputs.

Direct Costs and Manufacturing Feasibility

The basic cost of a product is tied to the cost of raw materials, based on various pricing methods such as FIFO, average purchase cost, last purchase price, and others.

Learn More about: Prices of Arabic and International Accounting Software

Additional Costs

Extra expenses like direct wages or electricity costs can be assigned either as a percentage or as an added value for each expense item.

Manufacturing Feasibility

This feature allows you to compare the available quantities of raw materials in the warehouse to determine whether producing a specific product is possible.

Key Advantages of Phenix

- Simplifying and organizing all your work smoothly.

- A demo version is available for download, offering a trial run of the software with limited use of its full features.

- An accounting system designed by experts to reduce errors in financial records.

- One-click monitoring of all imports, exports, and warehouse movements.

- Dynamic reports that support better decision-making.

- Automated processing of accounting transactions in line with company regulations and policies.

Subscription Cost and Number of Users

Subscriptions are tailored according to system requirements and the client’s specific needs. The addition of users is also based on demand, as there is no fixed pricing list or predefined packages for the system.

Read also: Best accounting software in Saudi Arabia

4- AccFlex

When comparing factory management and accounting software, the AccFlex accounting system is one to consider, as it covers all stages of manufacturing—from preparing raw materials to the production stage, through to delivering and selling the final product, as well as calculating profit and loss. This makes it one of the best accounting software programs suitable for managing manufacturing operations. It applies to all types of manufacturing activities.

Simply put, we can benefit from the AccFlex software in the manufacturing process in the following ways:

Production Process Management:

This refers to the entire manufacturing process from the very beginning. With the AccFlex software, you can manage production operations across all types of manufacturing, as it covers every stage, starting from preparing raw materials, moving through the production phases, and ending with delivering and selling the final product, along with calculating profit and loss.

Import Capability:

The factory accounting software supports importing data from Excel. It can also be used across multiple branches, linking them together through a central database, in addition to providing a complete system for controlling all transactions.

Product Coding:

AccFlex manufacturing software allows you to create an unlimited number of final products, define the components of each one, specify the types and quantities of raw materials used in production, and determine the cost of each product.

Accounting System for Factory and Production Management:

Manufacturing cost software is a specialized system for managing factories and production units across different sectors. AccFlex manufacturing software has been recognized as one of the best accounting software in Egypt and the Arab world. Its role is to cover the entire manufacturing and production cycle and to provide valuable insights through the range of reports it generates.

Advantages of the AccFlex Factory Accounting System

Flexibility:

AccFlex manufacturing software is more flexible than many other accounting software. It enables rapid transformation from manual systems to automated processes, helping companies implement changes quickly.

Quality Control and Process Evaluation:

The system allows for approval of batch numbers or accepted materials, which then move on to the next production stage. It also generates reports showing the variance between actual and planned costs.

System Integration:

AccFlex integrates seamlessly with purchasing, sales, general ledger, warehouse management, and human resources systems.

Technical Support & Free Trial:

A demo version is available for trial before purchase. Trained technical support staff are available at a high level to respond to inquiries, with ongoing technical assistance provided.

Subscription Cost and Number of Users

AccFlex pricing is designed to fit companies of all sizes, regardless of the number of employees. The software is sold as a complete system, not as a package. Prices start from $29, depending on the needs of your factory. The package includes installation, maintenance, operation, and user training, with unlimited users, since the system is sold outright.

Note: The price is very high for small businesses because it is sold as a complete system rather than by individual users, which may limit its appeal to smaller companies.

Read more: Best accounting software for mobiles (Android / IOS)

5- ERPNext software:

ERPNext offers distinctive features for managing the manufacturing sector and is considered an ideal choice for tracking all manufacturing activities and keeping up with the latest developments. Its most notable features include:

Manufacturing Setup

Easily prepare bills of materials (BOM) for production using ERPNext. You can define all components and costs from the initial manufacturing stage through to the final product. This helps you understand all the requirements needed for production, start the process efficiently and accurately, and increase your factory’s productivity.

Production Planning and Monitoring

This is achieved through detailed planning and defining the purpose of storing production materials, including:

- Determining the required product quantity.

- Understanding the raw materials needed for manufacturing based on the BOM.

- Creating production orders, which represent a key step in the process.

You can track production through:

- The stage of recording production orders and knowing their purpose.

- The stage of extracting raw materials from warehouses and beginning manufacturing.

- The final stage is where raw materials are transformed into finished products.

- ERPNext also helps meet actual required quantities in production orders, reducing waste and loss.

Automatic Warehouse Selection

With ERPNext, warehouse locations can be assigned automatically without manual intervention at each step of the manufacturing process.

You can also adjust store selection at any time, choosing the most suitable warehouse to improve efficiency and save time and effort.

Additional Features

Item Variants:

One of ERPNext’s most important features is the ability to store base items as templates, with each version saved as a variant. Attributes such as colour, size, or shape can be stored for each variant. For example, if your factory produces shirts in different sizes and colours, you can track each type and design separately. This is what’s referred to as “item variants.”

Multi-language Support:

ERPNext supports translation into more than 80 languages, allowing you to switch the system into your preferred language.

Technical Support, Free Trial, and Educational Guide

24/7 technical support is available to answer all inquiries and resolve issues. A 14-day free trial is offered (excluding the HR module). Educational video guides are provided to explain the system and address frequently asked questions.

Subscription Costs and Number of Users

| Plan Type | Cost Range | Notes |

| Monthly | $10 – $1,000 / mo | Price depends on system requirements. |

| Yearly | Equivalent of monthly × 12 | Packages do not include the HR management module or employee tracking. |

Conclusion

Finally, we can affirm that factory accounting software is an essential tool for managing factory operations. It helps analyze and organize accounts, while also enabling the handling of many different financial transactions. The criteria for evaluating the right accounting software for a factory vary according to the system’s ability to cover the entire manufacturing and production cycle, as well as the value of the information generated through the reports it provides. It is therefore very important to carefully analyze the factory’s needs and requirements, gain a clear understanding of what must be accomplished internally, and determine whether these tools and additional functions are necessary.