The Concept of Warehouse and Inventory Management, Its Importance, and Its Conditions

Table of contents:

- What is Warehouse and Inventory Management?

- What are the Tasks and Responsibilities of Warehouse and Inventory Management?

- What is the Importance of Warehouse Management?

- The Difference Between Warehouse Management and Inventory Management

- What are the Conditions for Achieving Effective Warehouse and Inventory Management?

- Tips for Effective and Professional Warehouse Management

- Best Warehouse Management Systems

- How does Daftra help you manage inventory and warehouses?

- Frequently Asked Questions

Some people believe that the task of warehouse and inventory management is limited to storing goods and operating materials. However, it plays a vital role that cannot be ignored to ensure the smooth and efficient flow of supply operations, while simultaneously reducing costs, planning budgets, and effectively allocating resources to facilitate production processes.

In turn, warehouse and inventory management coordinates all these stages and processes to ensure that products flow with the required quality, on time, to consumers and customers, thereby guaranteeing their satisfaction, supporting the organization’s good reputation, and highlighting its brand among competitors.

Therefore, in this article, we review the tasks of warehouse and inventory management, their importance, the conditions for effective warehouse management, and how to improve and develop them through best practices that help organizations enhance performance and increase competitiveness.

Summary of Key Points

- Warehouse and inventory management is responsible for integrating all warehouse operations into a comprehensive cycle that supports efficient management of inventory, supply, and import orders, thereby increasing operational efficiency, productivity, and profits.

- The tasks and responsibilities of warehouse and inventory management include maintaining inventory levels, collaborating with sales and purchasing departments, monitoring and tracking warehouse operations, organizing warehouses for storing goods and materials, communicating and negotiating with external parties such as shipping companies, preparing warehouse and inventory reports, planning budgets, and managing costs.

- The importance of warehouse and inventory management lies in executing sales orders and receiving inventory on time, managing inventory budgets efficiently, and adapting to sudden market changes to maintain the organization’s competitive position.

- Effective methods for warehouse and inventory management include automating tasks with warehouse and inventory management systems (WMS), complying with security and safety standards, defining inventory selection strategies, and using external logistics service providers.

What is Warehouse and Inventory Management?

Warehouse and inventory management is the management concerned with overseeing activities within warehouses, including monitoring storage quality, executing purchase and sales orders, and supervising logistics operations, including shipping, distribution, and receiving. It also involves scheduling warehouse staff by defining roles and responsibilities for each individual.

Warehouse and inventory management integrates all operations into a comprehensive, harmonious framework for execution, enabling efficient inventory management, resource allocation, and increased productivity while simultaneously reducing costs and achieving the organization’s objectives.

What are the Tasks and Responsibilities of Warehouse and Inventory Management?

Warehouse and inventory management is considered one of the most important departments in logistics services for businesses. About 82% of American customers and consumers are concerned about delivery delays or the negative impact of supply chain problems, which are handled by warehouse and inventory management.

This is according to a survey statistic published on Oracle’s website. We can summarize the responsibilities and tasks as maintaining inventory levels, collaborating with the sales and purchasing departments, monitoring and tracking warehouse operations, organizing warehouses for storing goods, communicating and negotiating with external parties, preparing warehouse reports, and planning budgets and managing costs.

Here are the details of the tasks and responsibilities of warehouse and inventory management:

1- Maintaining Inventory Levels

Warehouse and inventory management ensures maintaining the required inventory quantities and controlling excess inventory that leads to increased costs, or inventory shortages that prevent meeting customer needs, resulting in decreased sales and a negative impact on profits.

The warehouse management is responsible for accurately receiving inventory, handling returns, and periodically updating and calculating actual inventory levels.

See also: What is Periodic and Continuous Inventory and the Difference Between Them

2- Collaboration with Sales and Purchasing Departments

Roles between the sales department, purchasing department, and warehouse and inventory management are integrated. The warehouse management coordinates the purchasing budget to ensure the necessary inventory is provided without exceeding costs.

It also processes sales orders quickly and accurately upon receiving them, creates warehouse release orders, obtains approvals, and finally packages and prepares the requested goods and products safely for delivery to the customer while obtaining receipts.

This demonstrates the connection between warehouse and inventory management and operational processes, as well as other services such as sales, purchasing, and logistics.

3- Monitoring and Tracking Warehouse Operations

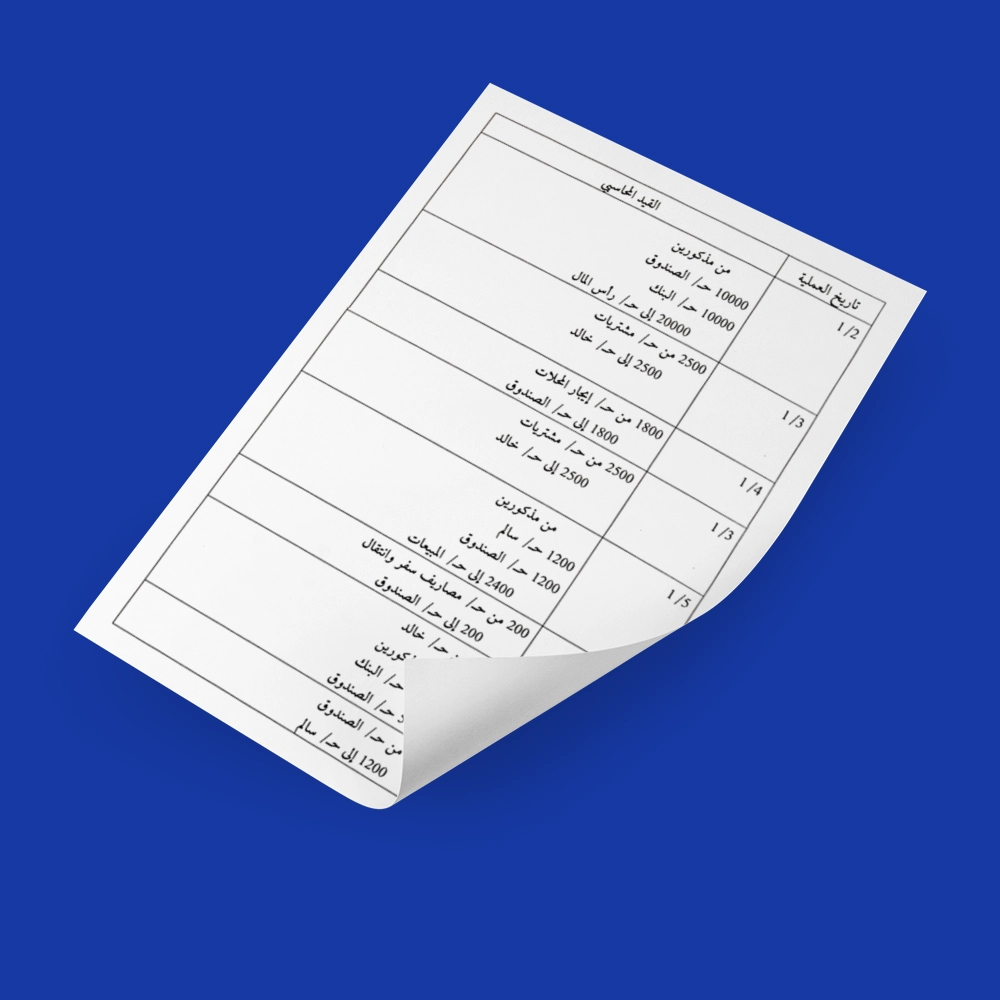

Warehouse and inventory management ensures that goods are safely delivered to warehouses, counts incoming and outgoing units to verify quantities, inspects the condition of goods, and documents goods in inventory records used for accounting operations.

Warehouse management also ensures the efficiency of Material Handling Equipment (MHE), which includes all tools and equipment used for transporting, distributing, and receiving inventory, such as various types of transport trucks and forklifts, electric, hydraulic, and water-based, among others.

4- Organizing Warehouses for Storing Goods and Products

Warehouse and inventory management is responsible for determining suitable areas for storing materials, goods, and products, and for using warehouse space efficiently to store the maximum inventory safely. These areas or spaces are chosen based on the type and size of the inventory, while adhering to the specific steps required for storing certain goods such as medicines or food products.

You may also be interested in: How to Code Product Items for Product Chain Tracking

5- Communicating and Negotiating with External Parties

Warehouse and inventory management is responsible for selecting shipping companies and services specialized in receiving orders from the warehouse and shipping them to various destinations.

Sometimes, the warehouse and sales departments collaborate to communicate with suppliers, compare them to choose the best on price and quality, and then negotiate the most suitable payment methods in line with the company’s capabilities and budget.

6- Preparing Warehouse and Inventory Reports

Warehouse and inventory management prepares inventory audit reports and warehouse-related reports, such as tracking how orders are executed according to required standards, and measures and evaluates the performance and efficiency of warehouse staff by analyzing the total number of orders completed within a specified time.

7- Budget Planning and Cost Management

Estimating costs and budget planning are among the responsibilities of warehouse and inventory management. It determines the required inventory based on future sales and profit goals, predicts demand from historical financial data, and estimates the costs of purchasing required materials and goods, as well as storage and transportation costs.

This is aimed at preparing an accurate budget with necessary provisions to handle any emergencies, such as market fluctuations or unexpected demand surges. Additionally, warehouse and inventory management monitors costs associated with inventory loss to identify causes, detect deviations that led to it, take corrective actions, and improve inventory turnover to reduce related costs.

Read also: What are Inventory Adjustments in Accounting and Their Objectives

What is the Importance of Warehouse Management?

The importance of warehouse and inventory management lies in achieving advantages and benefits. These advantages and benefits include processing and fulfilling sales orders, auditing inventory, strengthening relationships, avoiding problems, ensuring warehouse and inventory compliance, and maintaining a competitive position. Here are more details about the benefits and importance of warehouse management:

- Processing Sales Orders: Executing sales orders and ensuring the delivery of product inventory on time.

- Inventory Auditing: Facilitating inventory auditing and locating items through inventory records prepared by warehouse and inventory management, where inventory is accurately classified according to type, quantity, unit of measure, and serial number of each product unit ("barcode"). This leads to organized product searches and reduces the time and effort required.

- Strengthening Relationships: Supporting relationships with suppliers and enhancing customer satisfaction.

- Avoiding Problems: Preventing inventory shortage or surplus issues, thus achieving a balance between supply and demand.

- Ensuring Warehouse and Inventory Compliance: Adhering to safety, security, and quality standards related to inventory and warehouse labor.

- Maintaining Competitive Position: Warehouse and inventory management contribute to maintaining the organization’s competitive position by efficiently managing inventory budgets, enabling adaptability to sudden market changes.

Read also: What is the Best Warehouse Management Software

The Difference Between Warehouse Management and Inventory Management

The main difference is that warehouse management focuses on optimizing the efficient movement of goods within warehouses and reducing storage-related costs, whereas inventory management is a sub-goal of warehouse management, focusing on tracking inventory levels to ensure sufficiency for fulfilling customer orders.

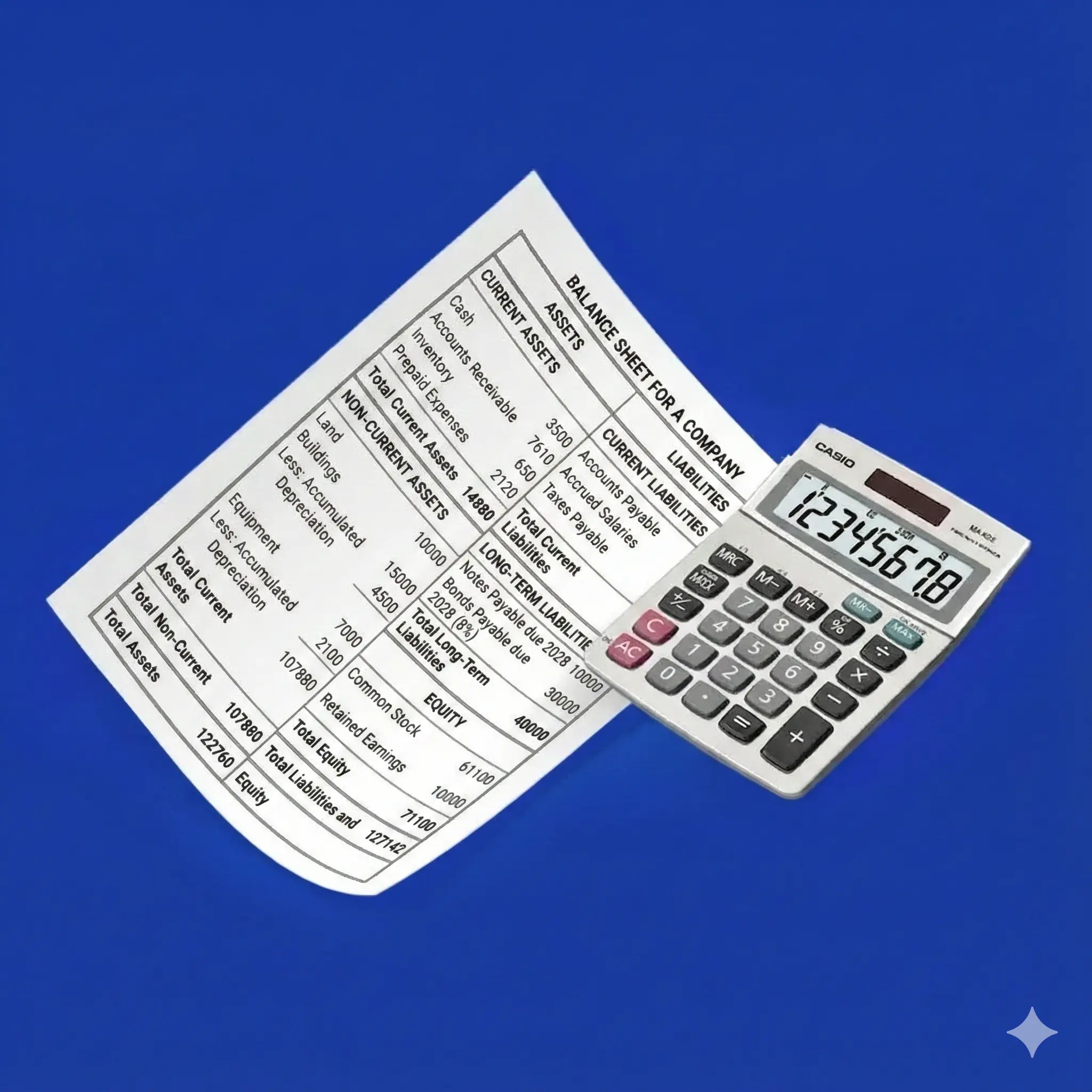

The following comparison clarifies the fundamental differences between inventory management and warehouse management:

| Difference | Warehouse Management | Inventory Management |

| Scope | Deals with everything in the warehouse, from raw materials used in production processes to finished products used for sale and revenue collection. | Deals with the final product ready for sale or distribution. |

| Tasks | Utilizing available storage space, receiving and shipping goods and materials. | Ensuring inventory levels are maintained and managing product demand. |

| Work Range | Handling operations that take place inside the warehouse on the inventory. | Strategic planning and control of the inventory itself. |

What are the Conditions for Achieving Effective Warehouse and Inventory Management?

The conditions for achieving effective warehouse and inventory management refer to adherence to the principles and characteristics of warehouse management, which include coordination, process tracking, having a clear plan, meeting customer needs, enabling flexibility, decision-making, protecting inventory, as well as effective communication, evaluation, and monitoring.

Here are more details in the following paragraphs:

- Coordination: The ability of warehouse managers to coordinate warehouse-related operations among responsible personnel, as well as the ability of warehouse management to control orders executed on inventory, knowledge of how to distribute and use tools and equipment in warehouse operations, and the flexible allocation of warehouse space to accommodate all types of inventory while leaving sufficient space for labor and equipment.

- Process Tracking: The ability of warehouse and inventory management to track every operation inside the warehouses to ensure quality and smooth workflow, and to resolve unexpected problems quickly and intelligently.

- Having a Clear Plan: By defining warehouse operation objectives, including sorting customer orders, types of goods, specified delivery times, purchasing needs from inventory, storage locations, and storage guidelines for certain materials.

- Meeting Customer Needs: The ability to meet customer needs and measure their satisfaction with handling and timely delivery is a key condition for effective warehouse and inventory management.

- Enabling Warehouse Flexibility: The ability of warehouse and inventory management to adapt to changing plans and adjust workflow efficiently and effectively, even in cases of delayed shipments due to weather changes, or the arrival of damaged goods due to transportation, shipping, or packaging errors.

- Supporting Decision-Making: The ability to make the right decisions based on data generated from warehouse and inventory management systems available in cloud accounting software such as Daftra, and to use this data to identify and analyze areas needing improvement and to forecast future requirements.

- Protecting Inventory: Adhering to quality standards in storage and providing security procedures to protect inventory from theft or damage, ensuring the safety of goods.

- Effective Communication: Establishing effective communication channels between warehouse and inventory teams and other teams such as sales, purchasing, and customer service to ensure information alignment and complete visibility that ultimately achieves organizational goals.

- Evaluation and Monitoring: Regularly evaluating and monitoring warehouse and inventory management operations using Key Performance Indicators (KPIs).

Read also: Inventory Evaluation Methods

Tips for Effective and Professional Warehouse Management

Here are the most important tips and effective methods that facilitate efficient and cost-effective warehouse and inventory management:

Automating Tasks

Automating warehouse and inventory management tasks and using Warehouse Management Systems (WMS) whenever possible helps process orders and returns quickly and accurately. It also reduces the burden of simple, repetitive tasks on workers, allowing them to focus more on tasks that require human intervention, such as quality inspection, packing, shipping, and distribution.

Daftra Cloud is considered a fully integrated ERP system for managing all business operations and enterprise resource planning. The warehouse and inventory management module allows organizing the movement of goods, materials, and products in warehouses in unlimited quantities, tracking inventory according to classification and price lists, issuing warehouse receipts, and conducting inventory audits using advanced tools.

Additionally, the system provides detailed reports on all warehouse operations and the performance of the responsible staff.

You can also download the stocktaking app on Google Play or from the App Store.

Compliance with Safety and Security Standards

Safe warehouses are a clear indicator of successful warehouse and inventory management. Therefore, it is essential to comply with safety and security standards for each warehouse by training employees to handle equipment properly and by regularly inspecting warehouses to detect potential hazards.

This helps prevent costly accidents that slow down the supply chain. Warehouse inspections also help monitor cleanliness, safety, and the condition of equipment used.

Defining Inventory Picking Strategies

Choosing the correct execution strategies for warehouse and inventory management in line with workload and order characteristics is essential for improving operational efficiency, ensuring smooth workflow within warehouses, and meeting customer requirements more effectively. Prominent picking strategies include:

- Batch Picking: Supplying multiple orders for the same product at once from the same warehouse location.

- Zone Picking: Assigning workers to fulfill orders in specific areas within the warehouse, which helps efficiently allocate resources.

- Expiry-Based Picking: Ideal for perishable items, giving priority to products approaching expiration, ensuring timely distribution while complying with safety and quality standards, and minimizing the risk of product obsolescence.

Outsourcing to Logistics Service Providers

Outsourcing to logistics service providers is crucial for enhancing warehouse management efficiency and achieving goals more effectively. This involves defining the vision and core requirements from the service provider, whether for storage, distribution, or inventory management, selecting a reliable provider with a strong market reputation, and monitoring Key Performance Indicators (KPIs) to evaluate provider effectiveness.

Best Warehouse Management Systems

Warehouse and inventory management systems help organize daily operations that occur within warehouses, reducing the time spent searching for and auditing goods. They also provide precise methods for tracking inventory, minimizing manual-entry errors, and preventing inventory shortages or surpluses.

A WMS system facilitates faster, more accurate order processing to enhance customer satisfaction and enables the collection and analysis of inventory-related data.

These systems help companies make informed decisions based on demand trends to determine the inventory levels needed for future demand.

How does Daftra help you manage inventory and warehouses?

Through Daftra’s inventory and warehouse management software, you will have access to many tools that simplify inventory management. The program provides notifications to track quantities in stock or newly added, full management from a single location, easy and quick conversion of warehouse receipts into invoices, and tools for accurate inventory auditing and detailed inventory reports.

Subscribe now to Daftra’s inventory and warehouse management program and get a free trial.

Frequently Asked Questions

What is the role of a Warehouse Manager?

- Maintaining inventory levels.

- Tracking ongoing operations.

- Responsible for organizing warehouses and storage facilities.

- Complying with safety standards and regulations.

What are the tasks of Warehouse Management?

- Receiving and storing goods.

- Storing and arranging items.

- Ensuring inventory safety.

- Preparing periodic monitoring reports.

- Business development.

- Coordinating with other departments.

What are the basics of warehouse management?

- Continuous organization.

- Using modern technologies to achieve better results, such as Daftra’s inventory management software.

- Training employees and raising awareness to ensure operations are performed accurately.

- Ensuring safety and applying all security procedures.

What are the types of warehouses?

- Public warehouses: Open to the public with government authorization.

- Private warehouses: Owned by specific business owners.

- Government warehouses: Used by the government for storing goods.

What are the types of stores?

- Stores by location: either near the market or the supplier, or inside the company or organization.

- Stores by usage duration: Either used year-round or temporarily to meet specific needs.

- Stores by materials: For example, fuel stores, spare parts, packaging materials, etc.

- Stores by functions: For example, refrigerated warehouses, customs warehouses, or record warehouses are used for specific functions.

What is the difference between inventory management and warehouse management?

Inventory management controls inventory and goods levels to meet needs and balance supply and demand, while warehouse management focuses on storing and organizing goods.

What is the most important element in warehouse management?

The most important element is safety for products and warehouse workers, and ensuring compliance with laws.

What is the relationship between warehouse management and other departments?

Warehouse management is responsible for providing and maintaining resources in an organized manner while preserving their quality. This supports other departments in their operational processes; therefore, warehouse management is an essential and complementary part of other departments.

In conclusion, warehouse and inventory management is the heart of logistics operations in commercial companies and is considered a fundamental pillar supporting the success of any organization in increasing productivity and profits.

Therefore, careful planning and the use of Enterprise Resource Planning (ERP) systems are essential to support warehouse and inventory management operations, ensuring smooth access for employees to goods and products to perform accurate accounting operations for warehouse transactions, avoid accounting errors, and ultimately deliver products and services to consumers on time, with the highest quality and lowest cost.